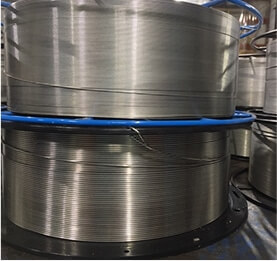

Spring wire technical detail

Technical Resources

Central Wire offers technical expertise to customers across the globe. Drawing on our unique capabilities and one of the industry’s largest technical teams, our resources can be put to work for solving any spring wire problem that arises in your application. Whether you need an engineered solution in an extreme environment of a few adjustments to optimize peak performance, Central Wire UK will work to achieve the performance you need.

Below is a collection of spring wire technical detail to help with understanding the general performance properties available from the many spring wire alloys manufactured by Central Wire UK. Specific details include Tensile Strength, Environmental Performance, and Thermal Treatments. Take a moment to review the information as presented, and contact us should you wish to discuss any particular details.

Download the Spring Wire Technical Guide

Specific details include Tensile Strength, Environmental Performance, and Thermal Treatments.

Download Detailed Properties of Select Alloys

Includes Modulus of Elasticity, Safe Working Temperatures, and comparisons of corrosion resistance and corrosion fatigue across Nickel Alloy and Stainless Steel Alloy Spring Wire.

Detailed Properties of Select Alloys

| Modulus of Elasticity | Maximum Safe Temp | ||||||||

| Material | Torsion 10′ | Tension 10′ | Magnetic | Corrosion Fatigue | T.P / T.S.** | High | Low | Corrosion Resiostance (general) | Spring Temper Range (KSI) |

| M400 | 10.0 | 10.0 | Varies | Good | 450 F | -320 F | Good | 145/180 | |

| K-500 | 10.0 | 10.0 | No | Good | 38/42 | 500 F | -423 F | Good | 145/195 |

| 600 | 11.0 | 11.0 | No | Good | 40/45 | 750 F | -423 F | Good | 170/230 |

| 601 | 11.5 | 11.5 | No | Good | Good | 120/205 | |||

| 625 | 11.0 | 11.0 | No | Excellent | 700 F | -423 F | Excellent | ||

| 718* | 11.0 | 11.0 | No | Good | 1200 F | -423 F | Good | 210/250 | |

| X750 | 11.0 | 11.0 | No | Good | 40/45 | 1200 F | -453 F | Good | 190/230 |

| 800 | 11.0 | 11.0 | No | Good | Good | 140/175 | |||

| 805 | 9.0 | 9.0 | Slight | Good | Good | 150/190 | |||

| 825 | 10.0 | 10.0 | No | Good | Good | ||||

| NS902* | 9.5 | 9.5 | Slight | Fair | Fair | 140/160 | |||

| H C-276 | 11.4 | 11.4 | No | Excellent | Excellent | ||||

| 302/304 | 11.0 | 28.0 | Slight | Fair | 40/45 | 500 F | -320 F | Good | 190/360 |

| 316 | 11.0 | 28.0 | No | Good | 45/50 | Good | 190/360 | ||

| 347 | 11.0 | 28.5 | Slight | Fair | 45/50 | Fair | 190/310 | ||

| 20Cb | 11.0 | 28.0 | No | Good | Good | ||||

| 17-7 PH* | 11.0 | 29.0 | Yes | Fair | 550 F | -320 F | 230/365 | ||

| TT-50 | 10.5 | 20.0 | No | Good | Good | 165/234 | |||

| 410 | 12.0 | 30.0 | Yes | Poor | 42/55 | 500 F | Fair | ||

| 430 | 13.0 | 28.0 | Yes | Poor | 42/55 | Fair | 160/200 | ||

**Approximate Ration of Torsional Proportional Limit to Ultimate Tensile Strength for Spring Wire

HASTELLOY is a registered trademark of Haynes Corp.

NS: Ni-Span-C H: Hastelloy TT: Tech-Tronic

Download Spring Wire Tensile Strength Detail

Compare Tensile Strengths across various diameters of common Nickel and Stainless Steel spring wire alloys.

Minimum Tensile Strength – Nickel Alloy Spring Wire

| Diameter Range Inches (mm) | Minimum Tensile Strength (psi) | ||

| 蒙乃尔®400 | Inconel®600 | Monel® K500* | |

| <0.028(0.71) | 165,000 | 185,000 | 165,000 |

| 0.0281(.071) – 0.057(1.45) | 160,000 | 185,000 | 165,000 |

| 0.0571(1.45) – 0.144(2.90) | 150,000 | 175,000 | 155,000 |

| 01441(2.90) – 0.229(5.82) | 140,000 | 170,000 | 155,000 |

| 0.2291(5.82) – 0.312(7.92) | 140,000 | 165,000 | 135,000 |

| .3121(7.92) – 0.375(9.53) | 135,000 | 160,000 | 135,000 |

| 0.3751(9.53)-0.437(11.10) | 130,000 | 155,000 | 125,000 |

| 0.4371(11.10)-0.500(12.70) | 130,000 | 155,000 | 120,000 |

| 0.5001(12.70)-0.563(14.30) | 120,000 | 140,000 | 120,000 |

| X750 | |||

| <0.250(<6.36) | 190,000 | ||

| 0.250(6.35) – 0.625(15.88) | 160,000 | ||

| After Heat Treatment | X750 | ||

| 0.012(0.30) – 0.250(6.35) | 220,000 | ||

| 0.2501(6.35) – 0.418(10.62) | 200,000 | ||

| 0.4181(10.62) – 0.625(15.88) | 180,000 | ||

Minimum Tensile Strength – Type 302/304 Spring Wire

| Diameter Range Inches (mm) | Tensile Range (psi) |

| <.009 (0.23) | 325,000 |

| 0.009 (0.23) – 0.012 (0.30) | 316,000 – 325,000 |

| 0.013 (0.33) – 0.016 (0.41 | 308,000 – 314,000 |

| 0.017 (0.43) – 0.022 (0.56) | 296,000 – 306,000 |

| 0.023 (0.58) – 0.028 (0.71) | 289,000 – 292,000 |

| 0.029 (0.74) – 0.036 (0.91) | 280,000 – 285,000 |

| 0.037 (0.94) – 0.045 ( 1.14) | 272,000 – 280,000 |

| 0.046 (1.17) – 0.063 (1.60) | 258,000 – 267,000 |

| 0.064 (1.63) – 0.080 (2.03) | 246,000 – 252,000 |

| 0.081 (2.39) – 0.094 (2.39) | 238,000 – 242,000 |

| 0.095 (2.41) – 0.120 (3.05) | 222,000 – 238,000 |

| 0.121 (3.07) – 0.148 (3.76) | 210,000 – 222,000 |

| 0.149 (3.78) – 0.162 (4.11 | 200,000 – 205,000 |

| 0.163 (4.14) – 0.187 (4.75) | 194,000 – 198,000 |

| 0.188 (4.78) – 0.207 (5.26) | 188,000 – 194,000 |

| 0.208 (5.28) – 0.225 (5.72) | 184,000 – 188,000 |

| 0.226 (5.74) – 0.278 (7.06) | 174,000 – 182,000 |

| 0.279 (7.09) – 0.362 (9.19) | 150,000 – 161,000 |

| .363 (9.22) – 0.500 (12.70) | 135,000 – 145,000 |

| >0.501 (12.72) | 130,000 |

Download Recommended Thermal Treatments

Review recommended stress equalizing and age hardening parameters of common Spring Wire alloys.

Recommended Thermal Treatments

| Stress Equalizing | Age Hardening | ||||

| Alloy | Temp (F) | Time (hrs) | Temp (F) | Time (hrs) | Maximum Safe Operating Temperature (F) |

| 蒙乃尔®400 | 575-650 | 1/2-1 | Not Possible | 450 | |

| Monel®K500 | 575 | 1/2-1 | 1000 | 4 | 500 |

| Inconel®600 | 800-900 | 1/2-1 | Not Possible | 750 | |

| Inconel®625 | Not Recommended | Not Possible | 700 | ||

| X750 Spring Temper | 875 | 3 | 1200 | 4 | 700 |

| X750 (>0.025″ diameter) w1 Temper (15% cold wor) | Not Recommended | 1350 | 16 | 1000 | |

| X750 (Annealed) Spring Temper (,0.025″ diameter) | Not Recommended | 1350 | 16 | 1200 | |

| X750 Spring Temper | Stress Relieved from Age Hardening | Solution Treat: 2100 High Temp Age: 1550 Regular Age: 1300 | 2 24 20 | 1200 | |

| Inconel® 718 Spring Temper | Stress Relieved from Age Hardening | 1325 1150 | 8 8 | 1000 | |

| Inconel®718 w1 Temper (15% cold wor) | Not Recommended | 1800 1320 1150 (Furnace Cool) | 1 8 8 | 1200 | |

| Ni-Span C 902 | 750 | 1-1/2 | 1100-1350 | 4-5 | |

| Alloy 805 (Temperature Compensating) | 750 | 1/2 | Not Possible | ||

| Alloy 825 | 800 | 1 | Not Possible | ||

| Alloy 20Cb-3 | Not Possible | ||||

| 302 Stainless Steel | 650-850 | 1/2 | Not Possible | 500 | |

| 316 Stainless Steel | 750-850 | 1 | Not Possible | 600 | |

| 17-7 PH Spring Temper | Stress Relieved from Age Hardening | 900 | 1 | 550 | |

| 17-7 PH (15% cold work) | Stress Relieved from Age Hardening | 1000 | 1 | 550 | |

| PH 15-7 Mo Spring Temper | Stress Relieved from Age Hardening | 900 | 16 (requires air cool) | 550 | |